Push Pull Control / Conduit Assemblies

Push Pull Assemblies are frequently used components in a variety of industries including automotive, aerospace and heavy equipment. These devices adjust and maneuver mechanisms such as machinery and activate specific functions. Without proper considerations in a Push-Pull Assembly, specific powered functions wouldn't work properly and would experience shorter lifespans.

Motion Control Technologies specializes in creating custom mechanical cable, lanyards, assemblies and more. With the help of our service, your business can maximize the use of Push Pull technology.

What Is a Universal Push-Pull Cable?

A universal push-pull cable is a throttle system consisting of two separate cables. The pull cable opens the throttle plates, while the push cable shuts them with a throttle return spring. The term "push" cable is misleading because it also pulls.

The term throttle typically refers to a mechanism that regulates or controls an engine's power or speed, like an automobile's acceleration pedal. In aviation, the thrust lever acts as a throttle. In train locomotion, the regulator acts as a throttle control for the steam flow.

A push-pull control's fundamental component is a solid wire with a plastic tube casing or spirally wrapped wire. Substituting a flexible cable for the solid wire allows the control system to be bent to facilitate routing. Different fittings can attach to the ends of the casing and cable for easier operation.

A push-pull throttle cable is an upgrade to the traditional automotive single-throttle cable linkage of many years past. When releasing or throttling down, the throttle grip engages the carburetor. It improves the single-throttle cable, as only a single spring is responsible for throttling down.

Push-pull cables can sometimes pair with a power takeoff to supply power to a secondary accessory from the same source, particularly in agricultural equipment like tractors.

Where Are Push Pull Assemblies Used?

Some call Push Pull Assemblies "Control Cable Assemblies." Both terms refer to the same technology as they enable machines to distribute the transmission of force across a system. Heavily used in outdoor tools, Push Pull Assemblies work to control the following actions:

- Acceleration

- Actuation

- Braking

- Brake control

- Choking

- Control systems

- Construction equipment

- Drive latches

- Hood releases

- Seat releases

- Push-pull controls

- Rotation

- Regulating

- Steering

- Throttle cables

- Throttle control

- Transmission shift

- Travel cables

Push Pull Functionality From Motion Control Technologies

Motion Control Technologies produces both standard push pull controls and custom push pull controls cable as well as custom conduit fittings and assemblies. Our cable controls are lightweight, flexible and economical.

Motion Control Technologies produces the following types of technologies:

- Push Pull controls: Push Pull Control Cables use a solid wire core inside a conduit to move the push or pull forces through planes and bends efficiently. We can provide our clients with both standard and custom Push Pull Controls to operate, position, open, and close components from a remote location.

- Push Pull cables: We create Push Pull cables that are a significant step up from traditional single throttle cable linkages. Our Push Pull cables work by throttling or twisting carburetors in an upward motion before releasing them back down. With our Push Pull cables for throttles, all it takes is a twist of the throttle to put the linkage back to idle in case of a failed spring.

- Pull cables: We design pull cables with complex mechanisms demands in mind and help you install a secure connection between two or more disparate areas. We create pull cables for conduit pulling, cable installation, large cable pulling, specialized purposes, and more.

- Push Pull assemblies: Motion Control Technologies creates Push Pull assemblies that effortlessly move your equipment and match your assembly application's exact specifications. We consider your cable requirements and build a Push Pull assembly that can withstand harsh conditions and provide effortless and reliable performance. We build custom Push Pull solutions for industries such as automotive, boating, electronics, medical, appliances, and more.

Push Pull Conduit Guide

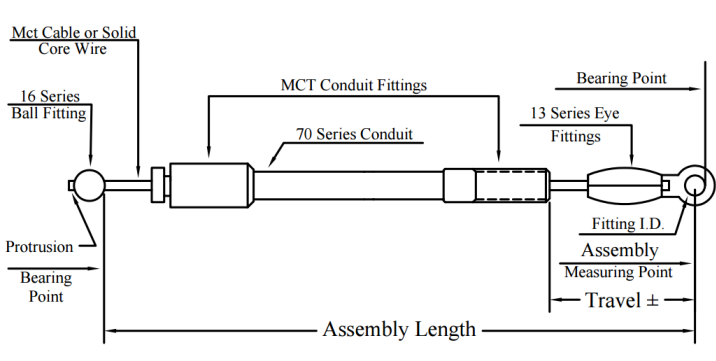

When engineering the right push pull control or conduit assembly, the picture below can help in choosing some standard fittings for the push pull control / conduit assembly. There are a few different cable types, however, for most push pull controls, an MCT Solid Wire Core is ideal in providing control of the strength and rigidity of your push and pull application. Or, a 1×7, 1×19 strand cable can offer the rigidity with additional flexibility without compromising strength.

Motion Control Technologies’ Conduit Fittings or bulkhead fittings can be used to secure the conduit portion of your assembly. Additionally, if you require threaded adjusters for snap groove fittings, we can offer a style custom for your application. We create Push Pull fittings and conduit guides in aligns with the following cable requirements:

- Conduit end

- Control heads

- Core wires

- Cable core

- Cable needs

- End fitting

- Lifetime performance

- Stainless steel

- Carbon steel

Push-Pull Cable Components and Characteristics

Among the components that make up a typical push-pull assembly are:

- Casing: A casing, also known as a conduit, guides the inner core of push-pull or pull-pull controls. Casings often consist of galvanized steel or nylon.

- Bulkhead terminal: Bulkhead terminals swage to casings and secure a push-pull control in a panel or bulkhead. Most terminal types consist of plated steel, stainless steel or brass.

- Cap terminal: Cap terminals allow the termination of the casing while enabling the cable or wire to pass through it.

- Clamp terminal: Clamp terminals fasten casings along their paths.

- Grooved terminal: Grooved terminals swage to the casing and secure a push-pull control into a slot or keyhole.

- Push-pull control: Push-pull controls drive chokes or dampers.

- Solid core wire: Solid core wire is ideal for applications requiring motion in both the push and pull modes. It also works well when a strand or cable is too flexible and additional stiffness is needed to actuate an item.

Manufacturers can customize push-pull cables to various lengths to meet required specifications.

Notes About Cable and Assembly Design

We incorporate the following principles into our product design for small and large companies:

- Push Pull Assembly: When powering a device, force is required in two directions of the assembly travel. Both the forces of pushing and pulling on a mechanical cable contribute to powering the machine.

- Pull Assemblies: Force to power a device is only required in the pulling of a mechanical cable.

- Motion transmission: With a motion transmission system, you can relay motion from one part of an assembly to the other side without altering the course or type of motion. There are five types of motion transmission — belt and pully, gear trains, chain and sprockets, friction gears, and worm and screw gears.

- Control cables: Control cables allow you to regulate and measure the transmission of automated processes according to UL rating.

- Cable application: Depending on the desired force and support exerted on a Push Pull assembly, you'll need to find a custom cable built for the specific requirements.

- Control cable application: Instrumentation and automation applications use control cables for regulating and measuring automated processes. You may want to choose a flat or woven cable application built specifically for robotics, assembly lines, power distribution, and more.

- Cable assemblies: With a cable assembly, you can arrange a group of cables or wires into one clean single unit that is easier to maintain, replace, and maintain. Choose the right cable assembly based on your intended indoor or outdoor purpose.

- Control assemblies: The right control assembly has the capability to automate and integrate your diverse group of OEM gear.

Loss of Motion

Backlash describes the motion lost in moving or actuating a push-pull cable. Although the cable design affects backlash, increasing the number of bends or tightening the bend angles will increase cable backlash. Less backlash is desirable, so minimizing bends and bend angles optimizes performance.

Another cause of motion loss is the deflection of the core wire rope under a compressive load. Due to compressive or tensile force, elastic strain in the core member also facilitates motion loss. The casing must be secure to avoid reacting to tension or compression modes.

Consider the Following

When you request the services of Motion Control Technologies, here are some factors we consider in the engineering of your Push Pull Assembly:

- Workload factor: What is the force that needs to get transmitted to power the device?

- Routing of the assembly: How is the assembly going to get anchored, so the Push Pull Assembly operates smoothly?

- Length and diameter: How much travel is required to power the device? The cable length and diameter of the inner wire and conduit matter when activating machinery.

- Cable specifications: What exact measurements are needed to support your Push Pull assembly's workload while remaining flexible and safe?

In a Push Pull Assembly, workload is crucial. Inner wires have the potential to buckle where they extend from the conduit. Fortunately, Motion Control Technologies knows how to get the diameter of a mechanical cable to increase the workload in pushing directions. Pull Assemblies are slightly more flexible and become effective in the routing process.

Push Pull Cable Assemblies at Motion Control Technologies

If your business needs custom push pull wire rope, Motion Control Technologies supplies the assembly to fit your needs. With our focus on customer service, we specialize in mechanical cable solutions that make your daily practices easier on your team. With over 30 years of experience in the cable and wire industry, we pride ourselves in prototyping, engineering and manufacturing the most superior yet economical motion control solutions.

For more information about Motion Control Technologies, contact us today to speak to one of our professionals.

You must be logged in to post a comment.